Email

Page Contents

Home

page

Pulser

index page

Improve the pulser

pump!

(or any air lift pump)

The pulser pump is a general purpose pump for

pumping water or air short distances. It isn't very efficient but (Hopefully!)

it makes up for it in other ways. Here is a way of dramatically improving

the performance for pumping water and (perhaps) of reducing the depth needed

to do pumping. This would probably work best with a split process pump.

The improvement may be achieved simply by using

balls of sponge like material (of a diameter suitable to fit the

pipe) and circulating them in the system. They act like pistons and reduce

the fallback. In this way, the efficiency is improved.

This has the potential to double the efficiency

of the pump as it pumps water!

I have done some experiments

but I haven't the time to complete them so it is over to you waterpower

hands-on scientist types! GOOD

LUCK

Some Guidelines.

1 The sponge should be

light and when it soaks water, it should sink.

2 I think that it should

be made of relatively hard material.

3 You may need some spacing

or timing mechanism to keep the balls the required distance apart.

4 Use hard clear pipes so you

can see what is going on inside. Perhaps Plexiglas or perxpex.

5 Perhaps you can power your

experiment with a small air pump. (Only the air lift part of a pulser

pump

is being changed).

6 Perhaps (if you are using

a pulser pump to power your experiment), you can have the air inlet to

the air lift section

about 70% or 80% of the maximum that it could be. You might not understand

why until you

try it out!

So there they

are, I hope some of you try the thing and make it better!

7 The pump should also work

without the sponge balls.

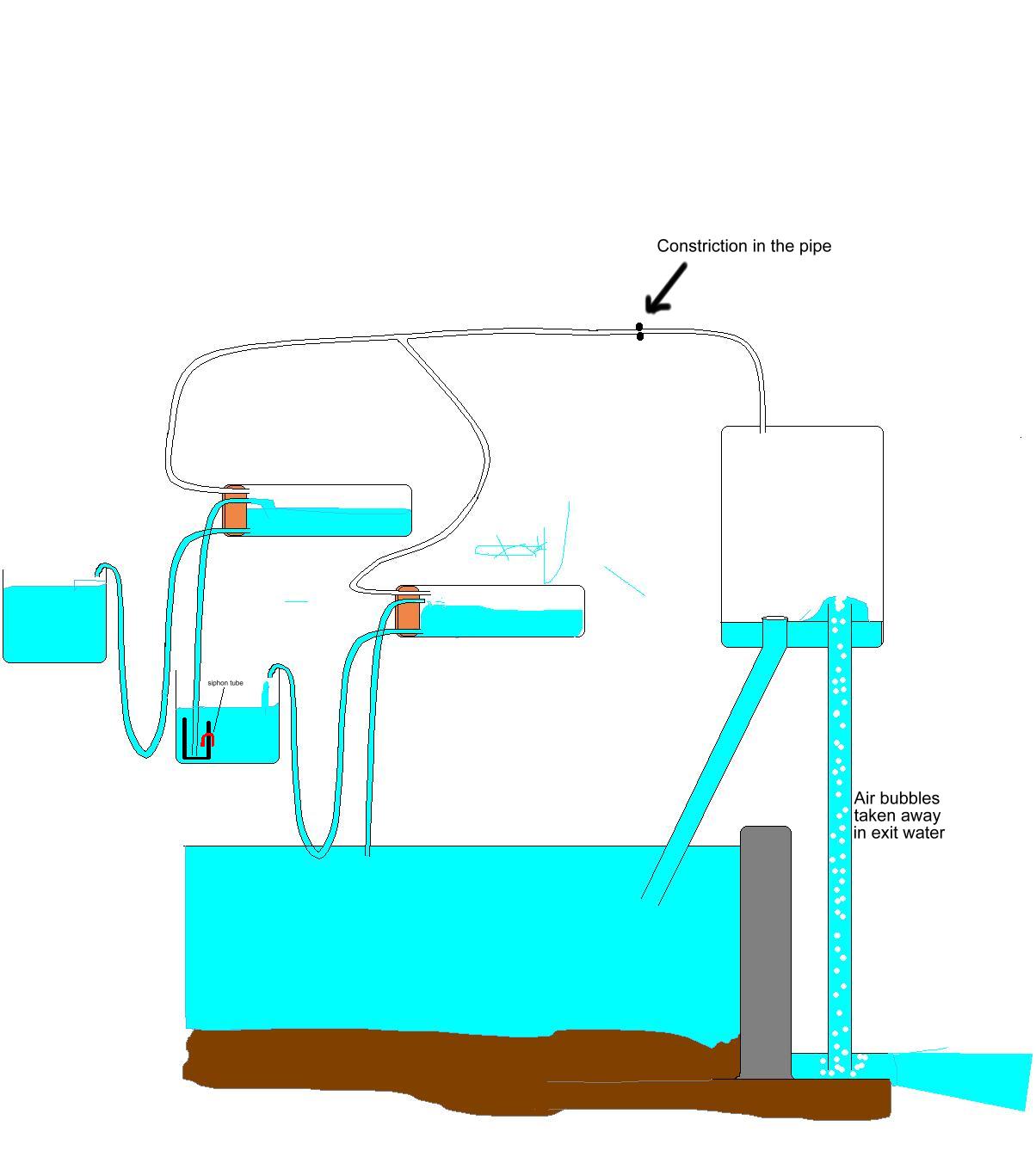

The animated picture lacks detail (only one sponge ball is shown),

scale, fall-back etc. but it should

give you an idea what I mean. Air to power the process comes in through

the

black pipe on the left. Improved image! 6th September

Pulser

pump model

Please use this link to build a simpler pulser modelmodel instructions

use this link to make a split process model (More complicated)

Suction

pump model

Below you will find a diagram of a suction pumping system which you can

make from jam jars, rubber bungs and rubber tubing! It need have no moving

parts. Instead of providing air under pressure as the pulser pump

does, it produces vacuum. It is very much a toy but one which will give

a lot of enjoyment as you try to tweak the process for better performance.

I now include an animation of the suction pump at Suction pump index

There are hundreds of ways to make it better!

You can use a valve instead of a constriction, you can have 2 sets

of pumping chambers, find the optimum height for pumping stages, or adapt

the process to pump in one long stage like a pulser pump.

It works scaled up too. I am not sure how tall you can make the suction

maker (pipe walls will collapse due to the vacuum). I do not think that

such a pump is good for the environment because a fish passing through

it would suffer swim bladder damage, aquatic insects would have their breathing

tubes damaged and I do not think that it will change the oxygen levels

in the stream in a beneficial way. This jam jar suction pump was actually

my first pump. I thought it up while distilling hexane in a laboratory

(boring job watching liquid bubble through pipes) and it is based on the

Krebs cycle which we learn about in biochemistry. The pulser pump

evolved from my experiments with it.

Email

Page Contents

Home

page

Pulser

index page