Sand washer 1st october 00

Email

Page Contents

Home

page

Applications

page contents

I will be adding to and changing this page a lot in the next month or so

Masonry sand is a valuable material and in many areas of the world

it is expensive or difficult to obtain a quality product.

In Ireland I often built walls with gravel cement mix (concrete!) and

rocks of course in the middle and the masonry sand on the outside

in the joints. This was because sand was so expensive.

In a sandy area, you can often dig up lots of apparently good material.

On closer inspection, you discover that it contains large quantities of

fine silt or clay. Clay is an enemy of masonry. It is a fine material which

bonds to the fine cement particles to produce a weak final product. The

answer is to wash the sand and separate out and remove the clay.

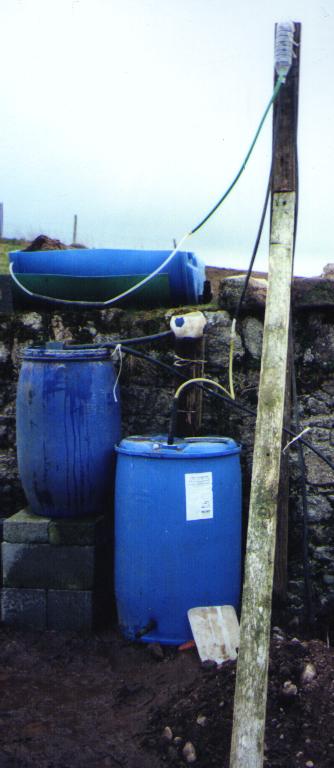

Behold the sand washer!

The sandwasher is powered by airlift. Airlift can be provided by a

compressor, a wind powered air pump, a pulser pump or other source of compressed

air. This is only a small working model. If you want to make one, you should

contact me first. I have made some improvements to the design. They are

small changes but they make for more even delivery of sand through the

system.

Wow, Complicated! But much of the system cannot be seen here! It is

even more complicated!

It is actually fairly simple. Air comes from the pulser pump (out of

picture) to the airlift piece (on the right underground).

The air causes airlift in the black pipe which sends water to the plastic

container at the top. (that water comes from the small blue barrel on the

left).

The water drains in 2 directions from the container, into the cut half

barrel on the wall and a small portion drains a different way to the large

barrel. The water draining into the half barrel washes sand out of

it. The sand falls through the counter current of water into the big barrel

and the silt is carried into the small barrel where it falls to the bottom.

Email

Page Contents

Home

page

Applications

page contents