How the pulser pump works,

benefits to the environment,

and details about how much

you can pump

This is detailed stuff!! Please take your time.

1 Hydropower

Explanation and picture

2 Working Principle

Hidden Bonus!! Environmental benefit

explained.

4 Estimate site potential

Your site What is it worth? Potential savings per anum

5 How much can you pump?

Working model and figures.

6 Set-up choices

You can make a pulser pump in many ways. Here are some.

Remind me to update the diagrams!

Email

Home

page

Pulser

pump index

Try the tables to navigate up and down this page

HYDROPOWER

Hydropower is the name of power derived from the energy of falling water.

Water falling 2 meters or more can be used to generate electricity.

Under 2 m, costs increase, returns and efficiency diminish

and in consequence, these sites are usually unused. There are a few ways

of using these sites, hydram pumps, waterwheels, etc. For various reasons,

these are rarely used.

The PULSER PUMP is another way of using

this power. Perhaps it suits your site and your intended use. If you are

in doubt, look up air lift pumps. Airlift pumps are old technology but

still in use today. Mostly for pumping water from very deep underground.

Water supply utilities, and industries which use lots of water commonly

use them. Similar physics governs the blowing of feed into farmers storage

bins from trucks.

The pulser pump works in broadly the same way. There is enormous

benefit to be had from such a Simple

system. Dig the hole, put in the pipes, divert part of the stream

through it and pump! It works automatically.

I will describe only the pumping of water and the pumping of

air for aeration in detail. However there are many possible uses. I will

provide you with only a general idea of what to do in those cases.

INTRODUCTION

Pulser pumps use the power of falling water directly to pump water

or air.

The pulser pump is cheap to make and to install, it has no moving parts

, it is reliable, needs little maintenance and it improves

the water quality in the river or stream in which it operates.

They can be used in flatter areas, with heads of half meter or

more and flows as low as 250 liters per minute (lpm). We recommend 500

lpm minimum.

Warning

Use a contractor and machines. I was stupidly risking my life.

My brother Edward died (aged just 20) on Sunday

21st May 2000 in a far less risky situation. Please don't take any risks

with your life.

see working model figures

How it works

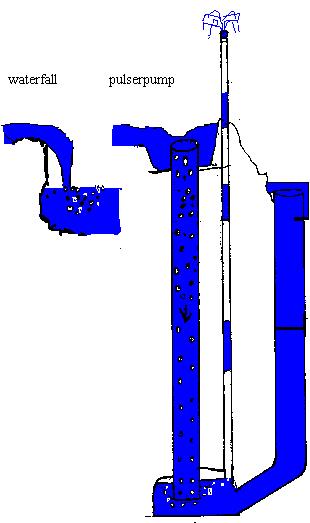

Stage one

Water falling in a waterfall carries air bubbles below the surface

in the next pool and they quickly return to the e

e

surface. In the pulser pump, the ''waterfall'' occurs in a vertical

pipe and the water flowing into the pipe blocks the return and forces the

bubbles deeper into the pipe. The bubbles continue down until they enter

a chamber where they separate from the water. The water returns to

the surface via an exit pipe and the air (under pressure due to the

depth) collects in the chamber. Energy from the falling water is now stored

in that air.

Stage two

The air from the chamber returns to the surface via a small diameter pipe.

The pipe contained water some of which falls back through the air as it

rises but much of it is carried to the top and forced

out of the pipe by the rising pressurized air. As water and air leave

the pipe at the top, they are replaced at the bottom and a dynamic equilibrium

is set up. It is hard to believe that 2.5 meters of air pressure can be

used to pump water 3 meters, 4 meters or even 8 meters higher! Fall

back makes it all possible.

Imagine the air pushing a column of water 2 meters long all the way

up the pipe. No problem there because the air column pressure is equal

to a column of water 2.5 meters high. Once it reaches the top and

is expelled, water rushes in to the bottom to replace it and the cycle

repeats itself.

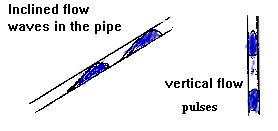

Stage two (inclined pipes)

The pipe taking the air away does not need to go straight up. If it rises

at an incline, it works too. This can mean a shorter simpler

all underground system. In this case, the air blowing in the pipes

makes waves in the water in the pipes. If the wave is high enough, it blocks

the pipe and travels rapidly through it. It isn't as efficient as going

vertically, it needs larger bore pipes but if it delivers enough water

for your needs, then why not?

HIDDEN BONUS!!!!!!

This type of pump acts as a water treatment

plant in the river itself! This is a very useful aspect. Can

anybody quantify its worth to the environment?

HERE is how it works:

As the stream water passes down the pipe mixed with the tiny air bubbles,

gas exchange takes place under ideal conditions. The bubbles are

tiny, the water is turbulent and the pressure is increased. Not only is

the water well oxygenated under these conditions, also volatile nitrogen

and sulfur compounds transfer to the air bubbles. Therefore the river becomes

oxygenated and cleaner and fresher! A better life for fish

and other freshwater animals. The calm well oxygenated water at the

exit will be a refuge for water creatures during pollution events which

typically reduce the oxygen levels.

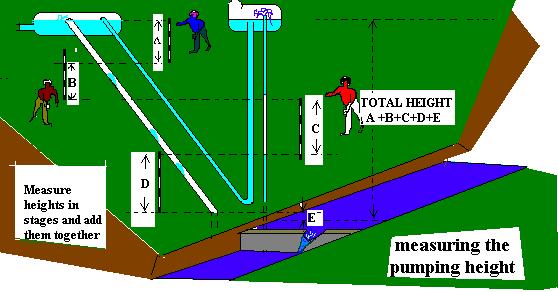

HOW MUCH WATER CAN YOU PUMP?

I will give you the figures for pumping up a vertical pipe.

The figure for pumping up an incline will be less and it depends on a lot

of factors. Assume it to be half of the vertical pipe figure.

You must first measure the height that you wish to pump. This can best

be done with a spirit level , a measure, a line level and some poles or

with a line level and some poles. You put the line level or the water

level between the poles between the pump and the use site and add

up the vertical drop on each pole between them. This total is your vertical

height (measure it in meters).

You can pump :

Liters per minute

Head X lpm at dam ÷ vertical height X 0.1

liters per hour

Head X lpm at dam ÷ vertical height X 6

liters per day

Head X lpm at dam ÷ vertical height X 144

I have done the figures in this way because

although the pump works all day, if you want to use the water rapidly at

certain times, then you must have enough storage capacity.

WORKING MODEL Approx.

Flow 260 liters per minute of water , head 0.5 m, going 2.5m deep and pulsing

to 3.6 m gave 4 liters per minute. The same setup gave 1.5 lpm at 5 meters

high. This was with a split process pump using 10 cm (4 inch) pipes for

the stream water and using 19 mm (3/4 in) for the pulsed water delivery.

The efficiency decreases like this as one pumps higher. On the other hand,

2 stages to 7 meters will give about 2 liters per minute with the

same setup. Going deeper also increases the efficiency. Perhaps you have

an abandoned well that you can use? Less pipes are used in that situation

and the well will not be filled in. The working model in the example

has just entered its second decade! It is in the hole in the Scary

picture. Apart from cleaning the sieve occasionally, there

has been no maintenance. If you can dig deeper, you should get a similar

efficiency at a similar height/dept ratio.

Once again, I recommend a larger flow than this, and the use

of 15 cm plastic pipes or bigger.

ESTIMATE THE SITE POTENTIAL

Choose the site carefully with enough head and flow and near to the

user, within 100 meters.

Examine a few alternative sites. Also you must recognize that

the site potential can only be estimated . Do not waste time worrying

about being super accurate. Stream and river flow varies enormously during

the year and from year to year. I suggest that you measure the stream flow

in a place where it is fairly rectangular, straight and fairly calm flowing.

Then you can make allowance for the height of the river. Is it higher

or lower than normal as you measure it ? A good guide is that if

a river is twice as high, about 3 times as much water is flowing.

You may then be able to use past experience to correlate your measurement

with the average flow in the stream.

MEASURING THE

FLOW

1 Chose a fairly straight part of the stream where

the cross section is approximately rectangular.

2 Place 2 poles in the stream 2, 3, or 4 meters

apart.

3 Time a piece of wood floating down the middle between

two poles. Repeat twice and divide the total

seconds by three. (Seconds)

4 Formula depth

(cm) X width (cm) X distance between the

poles (meters) X 4.5 ÷ seconds

This will give you the flow in liters per minute

MEASURE THE HEAD

Head refers to the distance that the water will fall from the

surface of the water in front of the dam to the surface of the water behind

the dam . You should measure this distance with a spirit level

or a water level. You can simply siphon water through a garden hose

over the dam. Once the water flows through the hose, simply

raise the end until the water no longer flows. Then measure the distance

from here to the surface of the water under the dam. The distance should

be 50 cm or more.

If you are making the dam from scratch, then you should get

advice from fisheries people, (and someone with engineering experience

if it is more than 0.5 m high).

Remember, these things should pay for themselves with

their work done. Home

Page

YOUR SITE ................ WHAT IS IT WORTH?

We will assume that you use the pulser pump throughout the year.. (My

figures, below, are calculated from figures in an edition of

Scientific America which was all about energy efficiency).

What is it worth? I will give the value per year in kWh

of electricity replaced, in coal saved and in savings in production of

carbon dioxide. If you wish to include the environmental benefit of oxygenating

the river, it is roughly equal to the figures for air pumping. Of

course, you get no economic benefit from this. It is, if you like,

your gift to the environment. In London, the Thames river is

oxygenated with big electric air pumps to produce this same effect.

YOUR SITE POTENTIAL SAVINGS PER ANUM

Pumping water

kW of electricity saved per year Head X

liters per minute ÷ 2.28

kilograms of coal saved per year Head X

liters per minute ÷ 3.72

CO2 reduced by kg per year

Head X liters per minute ÷ 1.79

Pumping air

kW of electricity saved per year Head

X liters per minute ÷ 0.76

Kilograms of coal saved per year Head X liters

per minute ÷ 1.24

CO2 reduced by kg per year

Head X liters per minute ÷ 0.55

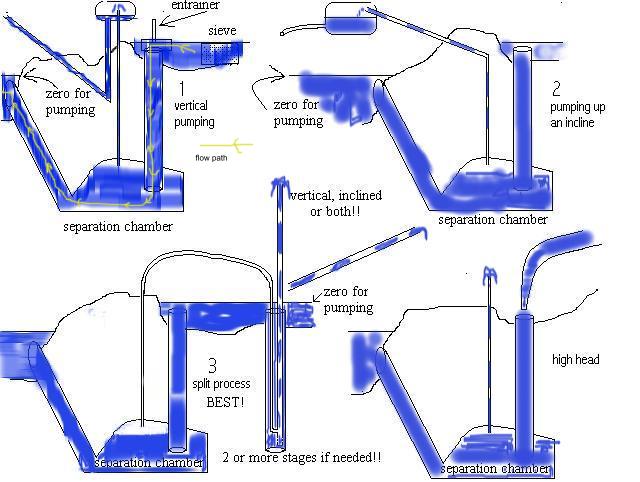

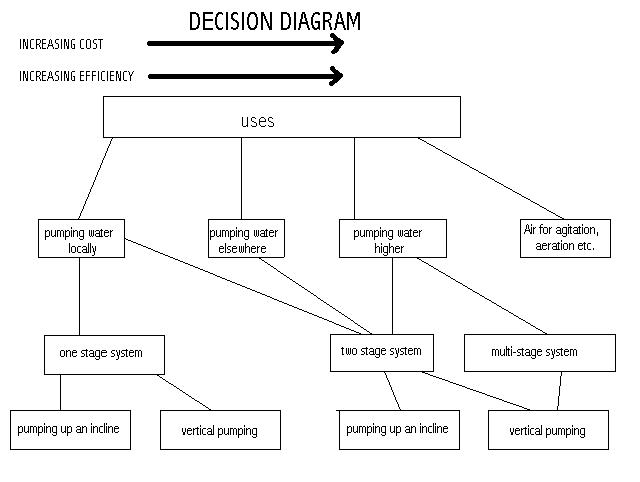

Different models for different situations

With any technology, you will be faced with different

models to deal with different situations, I strongly recommend No.

3 (split process) because of its versatility and efficiency.

Below is an overview of several ways of setting up the system. (Not

to scale). Use it to estimate material

costs. It should give you a rough idea of how

much pipe you will need to set up the system in one of the different ways.

I recommend No.3 (for lots of reasons!), No.2 is the simplest, but the

pipes to the user are generally bigger (more expensive), No.1 may

need guy wires to hold up the pipes, cost that in, and if the head is more

than 1.5 meters, No 4, a hydram or a low head hydroelectricity setup

may be an option for you. Be sure that they will be much

more expensive to build, but that they

definite options at 1.5m or more.

THIS decision diagram should help you make the compromises necessary

to

make a suitable system at the right price for your particular situation

Email

Page contents

Home

page

Pulser

pump index